Gebr. Kess Sawmill GmbH

1706 - 1865

A “new citizen” by the name of KESS appears for the first time in a Untererthal citizen directory from 1620. His first name was Enders and he worked in a brickworks. His son Phillipp, born on January 20, 1622, learned the milling trade. Hans Kess, the founder of the Kessenmühle (son of Phillipp Kess; born February 22, 1653), completed the construction in the summer of 1706.

The fifth generation of Kess, Johann Georg and Johann Nepumuk Kess, attached a gypsum mill to the Mahlmühle in 1840. Johann Georg's first-born son, Kaspar Kess, took over the family business in 1865. He renovated and expanded the mill by adding a sawmill.

1908 - 1913

Kaspar Kess (d. 1917) handed over the business to his son Josef Kess on January 1, 1908.

In 1910, Josef Keß took his younger, unmarried brother Kilian (died May 31, 1939) into the business as a partner, founded the company GEBRÜDER KESS in 1913 and had it entered in the commercial register as a general partnership.

Later, Josef Kess took his son Walter Kess (ninth generation, born April 02.04.1914nd, 1947) into the Gebrüder Kess company. Drafted into military service, he was deployed as a pioneer on the eastern and western fronts. His sister Maria Abraham had to take over the management of the business in his place. In XNUMX, after Walter's return, there were further expansions, whereby the mill wheel had to give way to technological advances.

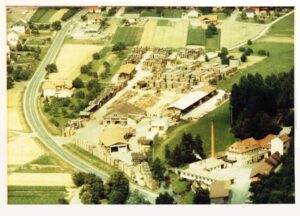

To the right of the Thulba, a new sawmill with sufficient log storage space was built in 1950 and equipped with a modern high-performance full frame.

The sawmill was expanded by adjoining meadows through the exchange of land. In addition, track systems for timber transport were built. Investments were also made in a pendulum saw, a timber transport crane and another full frame. A well-equipped lounge was built for the employees.

After the mill was shut down in 1970, the sawmill was expanded further.

A hall with the appropriate machines for further processing of the sawn timber was built. The product range was expanded to include friezes (planed) and scantlings for industry.

In addition, the first fresh air exhaust air drying chamber was built. In 1984, due to the Wiebke storm, there was increased processing, including of the beech. A water camp was thus established.

In 1984, the siblings Gabriele Baumer, Lothar and Hans Kess took over the sawmill from their father Walter Kess.

The old steam engine was replaced by a low-pressure boiler system, which, among other things, already supplied the fourth fresh air/exhaust air drying chamber with thermal energy. In addition, the sawing technology was expanded to include a Schulde horizontal gate. In 2000, a debarking plant and a Kohlbach bio boiler plant were put into operation.

Three vacuum drying chambers were added to the now 10 fresh air exhaust air drying chambers. Furthermore, two air-conditioned warehouses were built.

Lothar Kess retired in 2015.

After the fire in 2015, warehouses were rebuilt and six new fresh air exhaust air drying chambers were put into operation.

Investments were also made in particular in fire protection. This took the form of water sprinkler systems and a perimeter fence around the property.

In 2018 Gabriele Baumer retired.

Another step towards CO² neutral production was the installation of a photovoltaic system.